Robustness Analysis of Fractional-Slots Machines

Robustness analysis of Fractional-Slots Surface Permanent-Magnet

This activity consisted on a robustness study with respect to manufacturing defects of the most adopted fractional-slot surface permanent-magnet slot-pole configurations.

The objective of this activity was studying the influence of slot-pole choice on machine’s robustness with respect to unavoidable manufacturing imperfections.

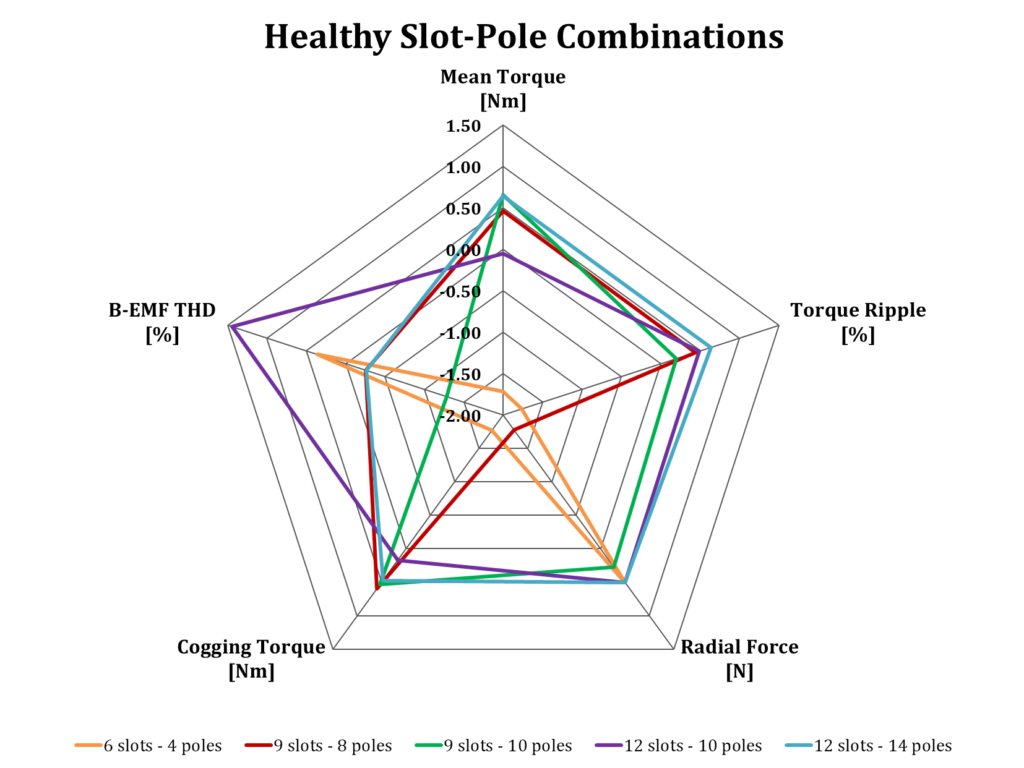

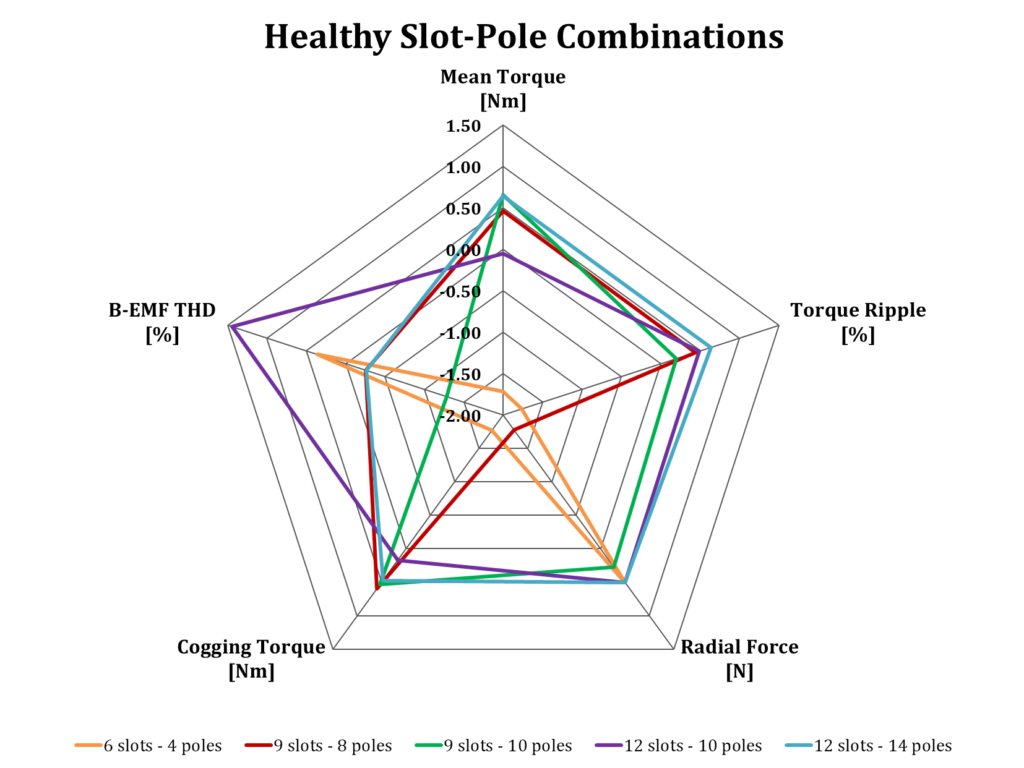

The first part of the activity was focused on the identification of the optimal slot-pole geometries via 2-D finite element.

Then the performance of healthy machines was compared with that of defective machines with respect a set of figures of merit such as mean torque, torque ripple, etc.

Results comparison allowed to determine a performance index in order to identify the most robust slot-pole configuration with respect to manufacturing production.

This activity consisted on a robustness study with respect to manufacturing defects of the most adopted fractional-slot surface permanent-magnet slot-pole configurations.

The objective of this activity was studying the influence of slot-pole choice on machine’s robustness with respect to unavoidable manufacturing imperfections.

The first part of the activity was focused on the identification of the optimal slot-pole geometries via 2-D finite element.

Then the performance of healthy machines was compared with that of defective machines with respect a set of figures of merit such as mean torque, torque ripple, etc.

Results comparison allowed to determine a performance index in order to identify the most robust slot-pole configuration with respect to manufacturing production.