MechSTOR

Dual-Rotor Ironless Electrical Machine. Raw Power Srl project in partnership with the University of Bologna.

This activity focuses on the design of an electrical machines for energy storage and release where it is stored as kinetic energy in a flywheel. The latter was designed to meet a photovoltaic household system of few kW.

The most critical issue is the minimization of mechanical and electric losses in order to guarantee a good conversion efficiency and a flywheel self-discharge duration of few hours during no load operation.

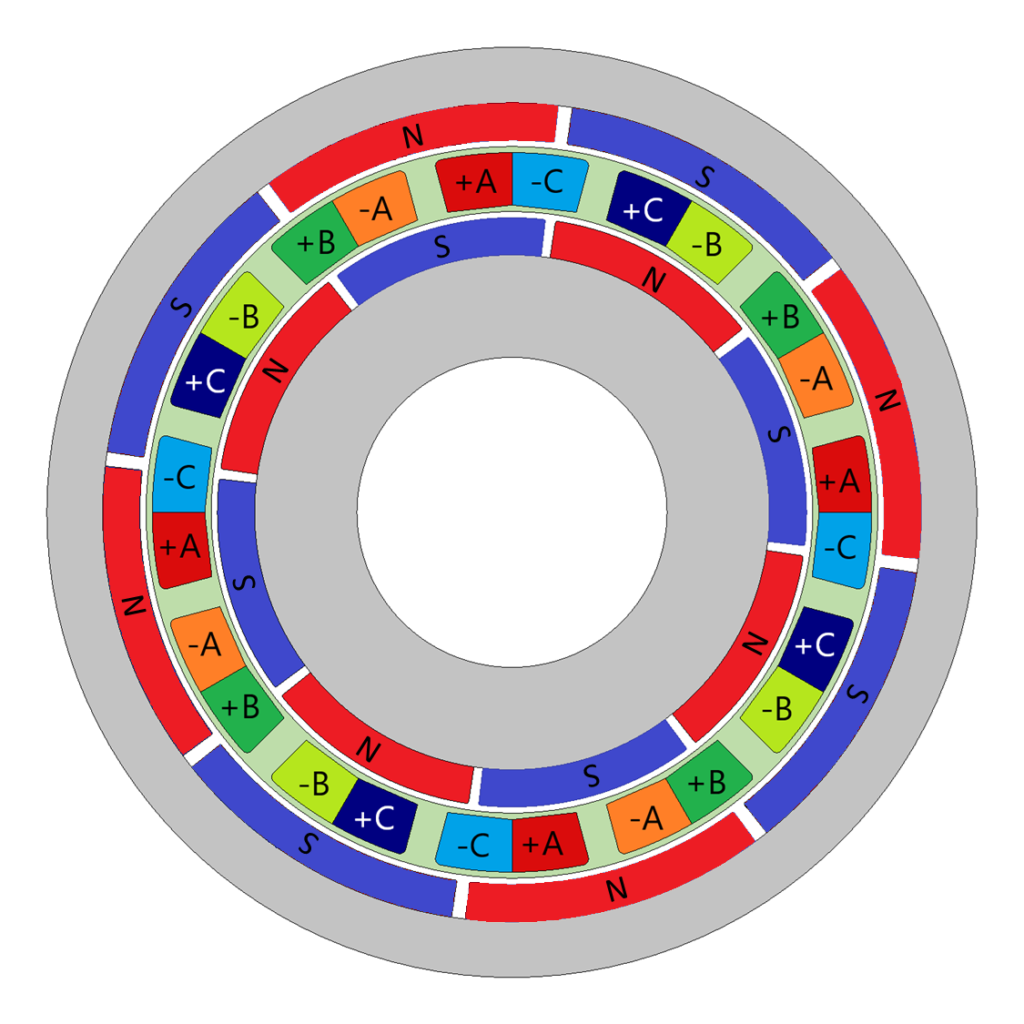

Three different electrical machine topologies were compared: a traditional surface permanent-magnet machine, a pure reluctance machine and a dual-rotor surface permanent-magnet machine.

The machines comparison was carried out considering the following figures of merit:

- Rated load performance;

- Load and no load power losses;

- THD of electrical machine currents as a function of power converter switching frequency;

- Annual stored energy inside the flywheel;

Activity results showed that the ironless machine is the best solution for the household flywheel application.

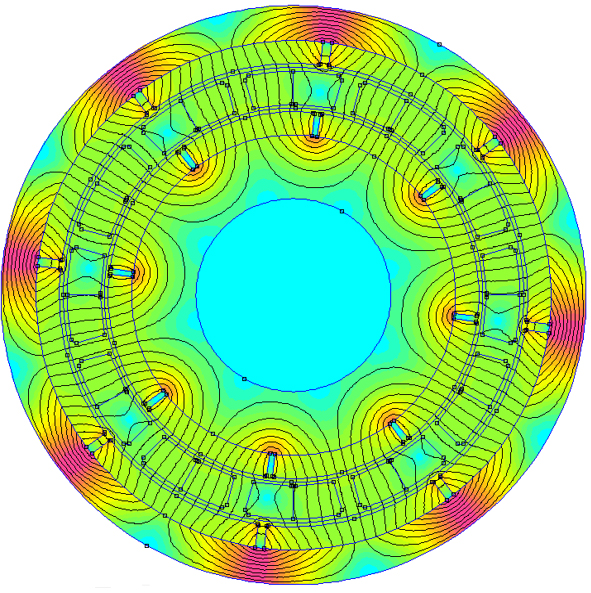

Finally, the electrical machine was prototyped and tested on a test bench for motor operation only. This activity was aimed to validate 2-D finite element results.

This activity focuses on the design of an electrical machines for energy storage and release where it is stored as kinetic energy in a flywheel. The latter was designed to meet a photovoltaic household system of few kW.

The most critical issue is the minimization of mechanical and electric losses in order to guarantee a good conversion efficiency and a flywheel self-discharge duration of few hours during no load operation.

Three different electrical machine topologies were compared: a traditional surface permanent-magnet machine, a pure reluctance machine and a dual-rotor surface permanent-magnet machine.

The machines comparison was carried out considering the following figures of merit:

- Rated load performance;

- Load and no load power losses;

- THD of electrical machine currents as a function of power converter switching frequency;

- Annual stored energy inside the flywheel;

Activity results showed that the ironless machine is the best solution for the household flywheel application.

Finally, the electrical machine was prototyped and tested on a test bench for motor operation only. This activity was aimed to validate 2-D finite element results.